A rigid Polymethacrylimide (PMI) foamROHACELL®

- HOME

- A rigid Polymethacrylimide (PMI) foam: ROHACELL®

Composite core material ROHACELL®

ROHACELL® handled by Polyplastics Evonik is a Polymethacrylimide (PMI) rigid foam manufactured by Evonik, our parent company. ROHACELL® looks like Styrofoam, but it has high heat resistance, superior mechanical strength, and excellent fatigue resistance, making it an excellent composite core material that contributes to weight reduction.

Sheet-shaped ROHACELL®

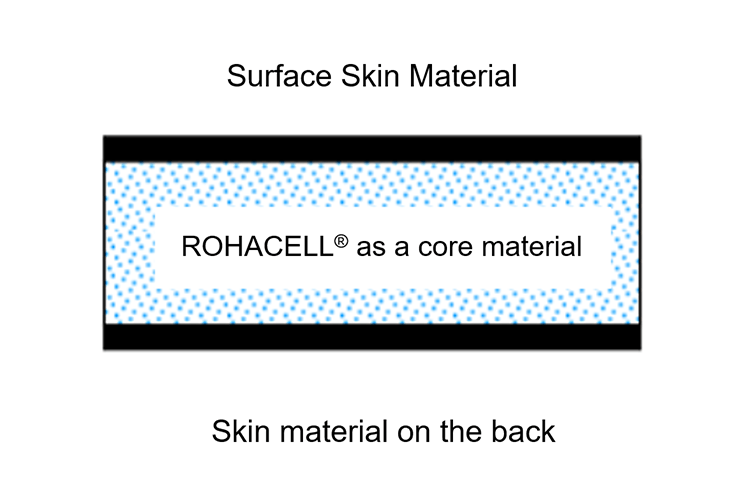

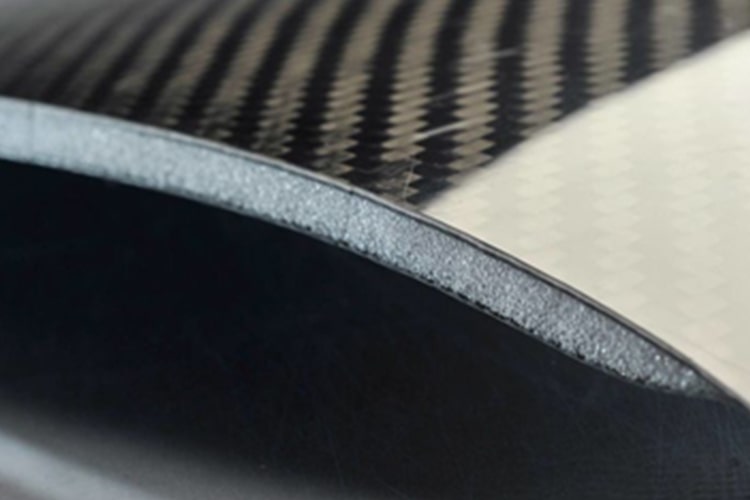

ROHACELL® is used as a core material in sandwich structures, sandwiched between skin materials such as prepreg (resin impregnated fiber fabric) and metal foils, as shown In the picture on the right. ROHACELL® is rarely used alone.

ROHACELL® contributes to high specific strength and weight reduction due to high heat resistance and closed-cell

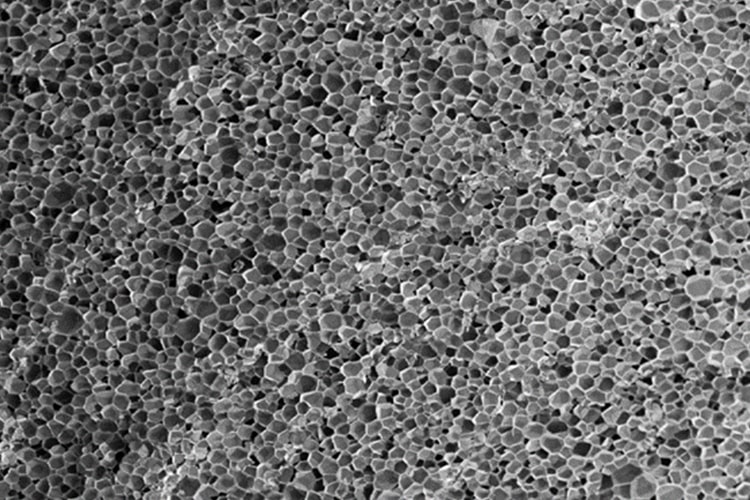

The most important feature of ROHACELL® is its high heat resistance. This heat resistance shortens the curing time of hardening matrix resins that making it possible to use a variety of thermosetting matrix resins. In addition, the rigid foam ROHACELL® is 100% closed-cell and has isotropic performance. Therefore, compared to other foam materials, it has a superior specific strength, so it is possible to use grades with smaller densities, which contributes to weight reduction.

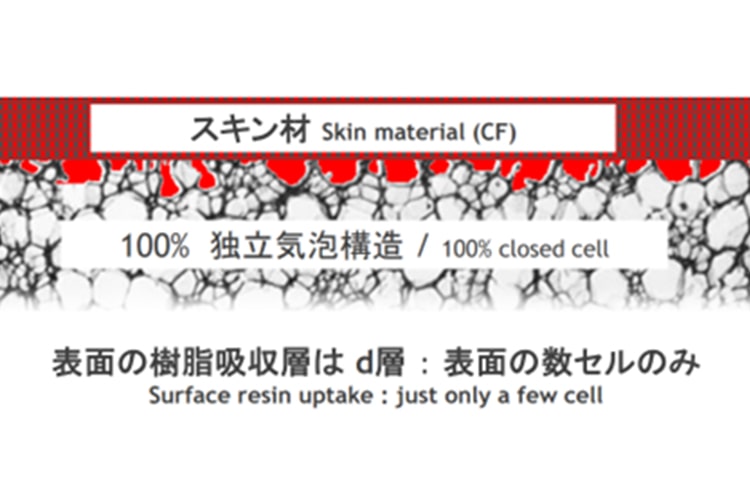

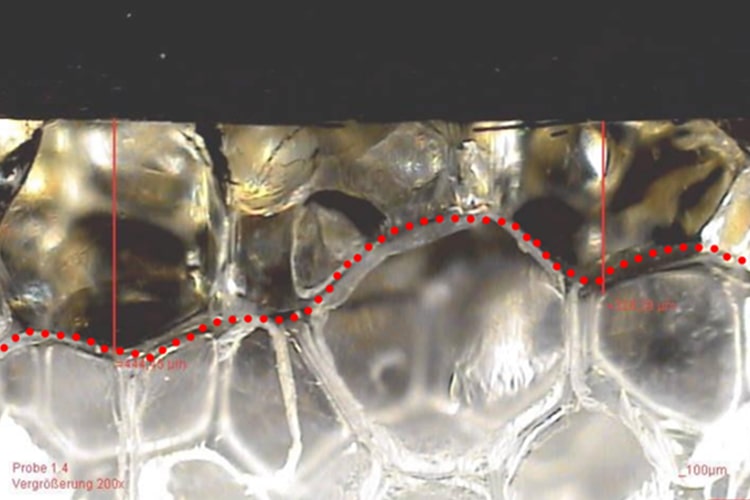

In addition, since ROHACELL® is 100% closed-cell, the thermosetting matrix resin does not impregnate inside ROHACELL® and stays near the surface, as shown in the picture on the right so the composite parts weight can be reduced.

Inclusion of thermosetting matrix resins on the surface of ROHACELL®

ROHACELL® with excellent processability and a high degree of design freedom

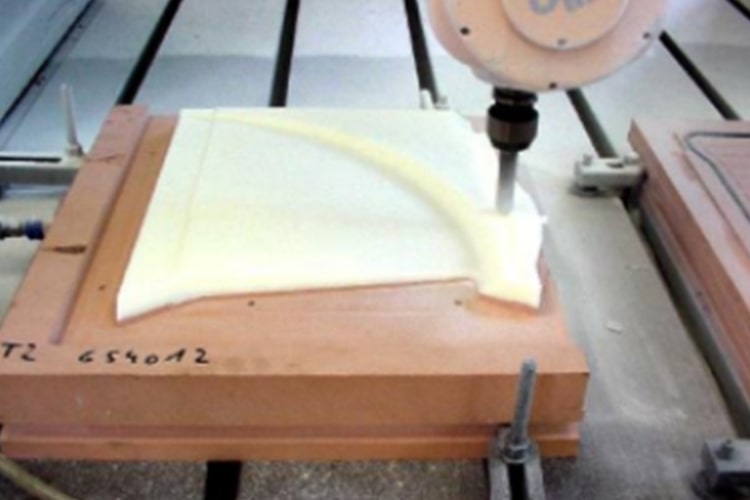

One of the features of ROHACELL® is that it can be easily processed. By using thermoforming and NC processing by programming, complex 3D shapes can be created, so there is design freedom.

In addition, since ROHACELL® has a full lineup, it is possible to optimize the composite parts manufacturing method and parts properties by selecting optimal grade by density, cell size and mechanical properties.

Thermoforming and NC processing of ROHACELL®

ROHACELL® Grade List

Evonik's PMI (polymethacrylimide) rigid foam ROHACELL® is widely used as a high-performance composite material in various fields such as aerospace, medical and automotive. ROHACELL®combines excellent heat resistance with superior mechanical strength despite of very low densities. Unlike other rigid foams, ROHACELL®’s higher heat distortion temperature and higher compressive strength is its characteristics. Some grades can be further enhanced characteristics by heat treatment. In addition, ROHACELL® is closed cell, so the matrix resin can only be filled in the open cell at the surface. As a result, extra matrix resin does not penetrate into the foam, preventing unnecessary weight gains and at the same time contributing to processability by vacuum fixation. In addition to that, ROHACELL®can also be thermoformed for complex shapes.

Click on any of the products listed below to see the property table. If you have any questions, please contact our sales representative.

| Grades | Properties | Size of cells | Density | Maximum degree of cure | Applications |

|---|---|---|---|---|---|

| ROHACELL® IG-F 31IG-F | Standard Grades | M | Low density | 130℃ | Automotive;General Industry;Sports&Lifestyle;Medicl |

| ROHACELL® IG-F 51IG-F | Medium density | ||||

| ROHACELL® IG-F 71IG-F | |||||

| ROHACELL® IG-F 110IG-F | High density | ||||

| ROHACELL® 51HERO | High Heat Resistance, High Compressive Strength, High Elongation at Break, Scratch Resistance, Arade for Aerospace Structural Components | M | Medium density | * 180℃ | Aerospace |

| ROHACELL® 71HERO | |||||

| ROHACELL® 110HERO | High density | ||||

| ROHACELL® 200HERO | |||||

| ROHACELL® 51WF | High Heat Resistance, High Compressive Strength, Large Cell Size | L | Medium density | 130℃ | ** Automotive;Aerospace;General Industry |

| ROHACELL® 71WF | |||||

| ROHACELL® 110WF | High density | ||||

| ROHACELL® 200WF | |||||

| ROHACELL® 51RIMA | High Heat Resistance, High Compressive Strength, Small Cell Size | S | Medium density | 130℃ | Automotive;Aerospace;General Industry;Sports&Lifestyle |

| ROHACELL® 71RIMA | |||||

| ROHACELL® 110RIMA | High density | ||||

| ROHACELL® 71XT | High Heat Resistance, High Compressive Strength, Large Cell Size | L | Medium density | 180℃ | Automotive;Aerospace;General Industry |

| ROHACELL® 110XT | High density | ||||

| ROHACELL® 51S | Excellent fire resistance, self-digesting | L | Medium density | 130℃ | Aerospace;Railway;Shipbuilding |

| ROHACELL® 71S | High density | ||||

| ROHACELL® 110S | |||||

| ROHACELL® 31HF | High dielectric properties | S | Low density | 130℃ | Aerospace;General Industry;Medical |

| ROHACELL® 51HF | Medium density | ||||

| ROHACELL® 71HF |

* HERO is a heat treatment grade.

** The 71WF and 110WF are not suitable for use in automotive or general industrial applications.

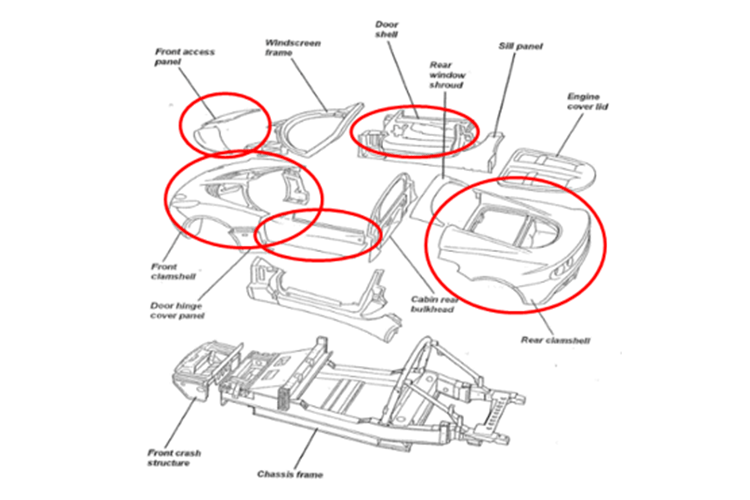

High-performance ROHACELL® used in the aerospace and automotive fields

ROHACELL®, a highly functional rigid foam, is used in a wide range of fields such as automobiles and aerospace. You can check what other fields, applications, and how it is used from the following.

Applications for ROHACELL®

Automotive

Aerospace

General Industry

Sports & Life style