PEEKVESTAKEEP® / VESTAKEEP® -J

- HOME

- PEEK VESTAKEEP® / VESTAKEEP® -J

PEEK with top-level functionality in Super Engineering Plastics

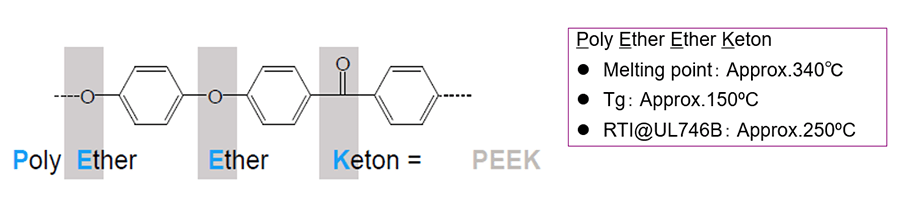

VESTAKEEP®, PEEK (Polyetheretherketone) , is a thermoplastic crystalline resin and has a high level of the key properties required high heat resistance. VESTAKEEP® has a very high potential to be involved in future technological innovation, so VESTAKEEP® has been used and studied for advanced applications and products in a wide range of fields such as the automobile, semiconductor, aerospace and medical industries.

In general, PEEK is often associated with processing challenges due to its high processing temperature (melting point of about 350℃). However, VESTAKEEP® is actually suitable for a wide range of processing methods. This includes not only main mass production methods for thermoplastic resins such as injection molding, extrusion molding, and powder coating, but also the latest techniques like FDM (Fused Deposition Modeling).

PEEK with excellent heat resistance

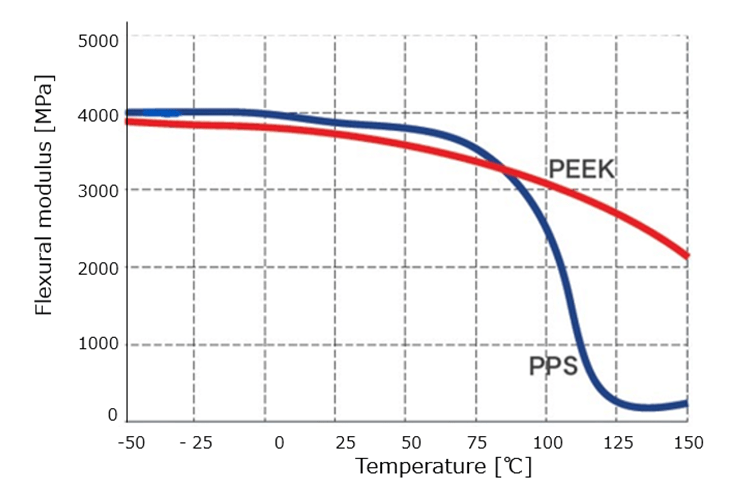

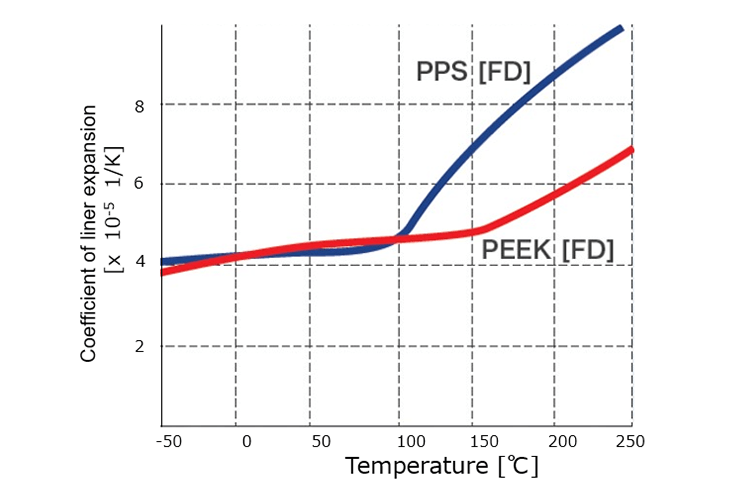

VESTAKEEP® is one of the thermoplastics whose mechanical properties are less sensitive to temperature, making it easier to use and design in high-temperature environments. For example, VESTAKEEP® has better heat resistance than PPS (polyphenylene sulfide) which is widely used as a high heat resistant engineering plastic. This advantage can be seen in the right graph, which shows the temperature dependence of the mechanical properties of VESTAKEEP® and PPS materials. PPS’s Tg is about 90℃, while VESTAKEEP®’s Tg is about 150℃.

Mechanical properties of resins generally decrease when exposed to higher temperature, but, VESTAKEEP® has high heat resistance. Therefore, VESTAKEEP® highly keeps mechanical properties even at high temperatures.

VESTAPKEEP® with high toughness, excellent abrasion resistance and fatigue resistance in high temperature environments

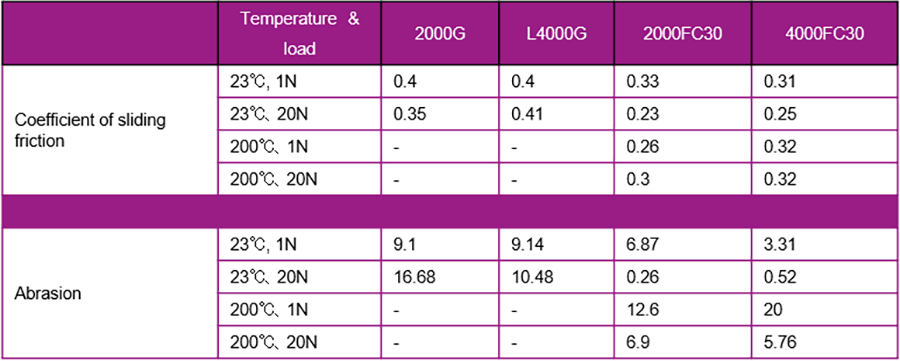

One of the features of VESTAKEEP® is high toughness and excellent abrasion resistance. Therefore, VESTAKEEP® is suitable for sliding parts that are subjected to repetitive loads such as gears and washers. POM (polyacetal) and PA (polyamide) are generally used for sliding materials, but VESTAKEEP® has high heat resistance, so VESTAKEEP® performs very well in harsh operating environments such as high temperature environments. In addition, VESTAKEEP® also has the highest level of fatigue resistance, so it is possible to reduce or eliminate maintenance work by switching from existing engineering plastics to VESTAKEEP®. On the other hand, by replacing metal with VESTAKEEP®, it is possible to reduce the noise of the drive and it functions as an important material for creative applications.

VESTAKEEP® with high chemical and hydrolysis resistance in high temperature environments

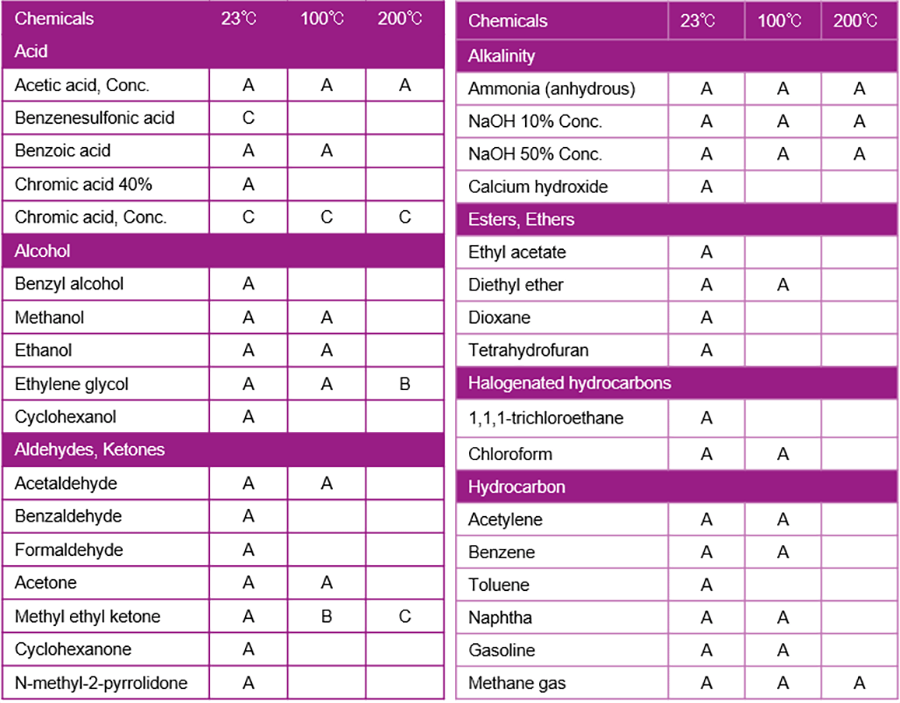

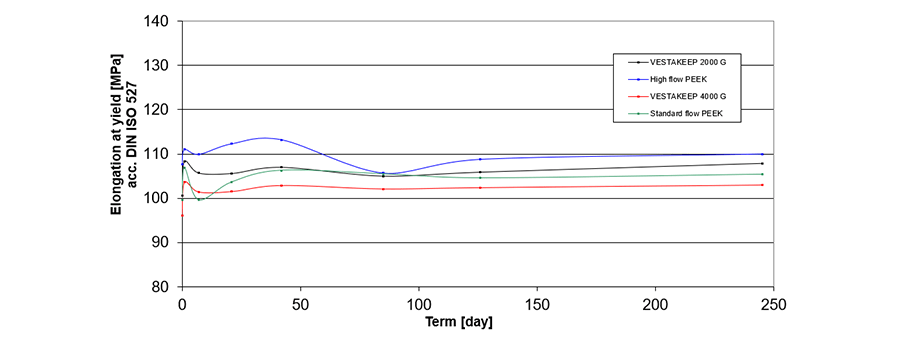

VESTAKEEP® has the second highest chemical resistance after fluoropolymers. VESTAKEEP® has been used for many years in the semiconductor manufacturing process, where it is exposed to contact and immersion at high temperature. In addition, PA (polyamide) and TPU (thermoplastic polyurethane elastomers) has weakness in hydrolysis resistance. Unlike those material, VESTAKEEP® have excellent hydrolysis resistance. Moreover, VESTAKEEP® has one of the highest levels of radiation resistance among various resins. Due to the advantage of these features, VESTAKEEP® is used in parts of medical equipment that require gamma ray and steam sterilization, as well as parts of oil and gas drilling equipment that are exposed to high temperature and high humidity. Below is a graph showing the chemical resistance and hydrolysis resistance of VESTAKEEP®.

VESTAKEEP® for highly safety and high reliability

The market's attention to VESTAKEEP® is increasing year by year. Polyplastics-Evonik's technical center located in Aboshi, Himeji City, Hyogo Prefecture, provides technical support from product design to processability. We make great effort to create value-added products to meet the needs of our customers.

VESTAKEEP®, a top-class super engineer plastic, is most suitable material for applications which require very high heat resistance, safety and reliability. VESTAKEEP® is used in a wide range of fields such as automotive, aerospace, industrial applications and medical applications. If you want to know more details about VESTAKEEP®, you can check more details in what kinds of fields and applications VESTAKEEP® is used as below.

PEEK gears and seal rings

Application for PEEK

Automotive

- Gears for Automotive

- Application of Insulation Coating Material for Coil Winding Inside Motors

- Sealing Ring

Aerospace

General Industry

Medical