NewsPress release

- HOME

- News

- Press release

- World's first case to remove impurities from Biodiesel Fuel by membrane separation

NEWRelease2022.08.22World's first case to remove impurities from Biodiesel Fuel by membrane separation

Developed a breakthrough commercial-based purification equipment

Muromachi Chemicals Inc. (Head Office: Omuta City, Fukuoka Prefecture, president: Junichi Aoki), Suiko Giken Co., Ltd. (Head Office: Kasuga City, Fukuoka Prefecture, president: Masaki Niihara), Ken Seisakusho Co., Ltd. (Head Office: Chikuzen-cho, Asakura-gun, Fukuoka Prefecture, president: Ken Matsubara), RITA Co., Ltd. (Head Office: Shinjuku-ku, Tokyo, president: Yoshiya Kitagawa) and Polyplastics-Evonik Corporation (Head Office: Shinjuku-ku, Tokyo, president: Tadashi Kanai) have jointly developed a biodiesel fuel refining equipment with four companies.

With the cooperation of Nishida Shoun Co., Ltd. (Head Office: Shingu-cho, Kasuya-gun, Fukuoka Prefecture, President: Masumi Nishida), we worked on demonstration evaluation and data collection, and completed the development of new technology. We have developed a purification system (patent pending) to produce high-quality biodiesel fuel by using solvent-resistant membrane, and it is scheduled to be launched in September 2022. Compared to the conventional "distillation method", it is more efficient with less enerygy and environmental friendly method.

In Japan, from the perspective of reducing the use of fossil resources and decarbonization (reducing CO2 emissions), there are many businesses that manufacture biodiesel fuel from used cooking oil as a raw material and use it as an alternative to diesel.

Refining equipment

When biodiesel fuel made from used cooking oil is used for a vehicle as an alternative to diesel, there are many problems such as clogging of the muffler due to impurities such as free fatty acids derived from raw materials and free glycerin generated in the manufacturing process. As a solution to these problems, there are methods or equipment to remove impurities by distillation method to have high quality biodiesel fuel, but due to the danger of distilling fuel, less capacity (low yielding) and cost (high energy consumption), it is only applied limitedly.

To solve these problems, we set up a development team and challenged to remove impurities by an innovative way that has never existed before.

Biodiesel Fuel

A fuel produced by transesterification from palm oil, soy oil, rapeseed oil, sunflower oil, and oil derived from algae, or used cooking oil is called as biodiesel fuel. As an alternative to diesel for automobiles, ships and so on, it can be mixed with diesel or 100% biodiesel fuel can be used without changing the combustion engine side.

Challenge: Impurities in Biodiesel

It is considered that some impurities such as unreacted substances and free fatty acids are remaining in biodiesel fuel even after sufficient water washing, filtration, and dehydration in the production process. In addition, biodiesel fuel produced from used cooking oil contains a lot of oxidized free fatty acids, which cause coloration and are considered to be mixed into biodiesel fuel as impurities.

Solution: *High purity purification of biodiesel by solvent-resistant

By special purification process using a solvent-resistant membrane, it is possible to produce high-quality biodiesel fuel with few impurities. Compared to conventional distillation methods, it is high quality, higher yielding, more economical and more safety.

◆ High quality: Improved ester content (94%→99%, *Impurity removal) to produce high-

quality biodiesel fuel

◆ High yield: The yield of the distillation method is about 75%, while the membrane

separation membrane can achieve high yield as 90%.

◆ Cost Saving: It can be much cheaper refinery process than distillation method

by reducing energy cost.

◆ Safety: Unlike the distillation method, the membrane separation is much more

safe due to no danger of thermal treatment to fuel at high temperature (several hundred ° C).

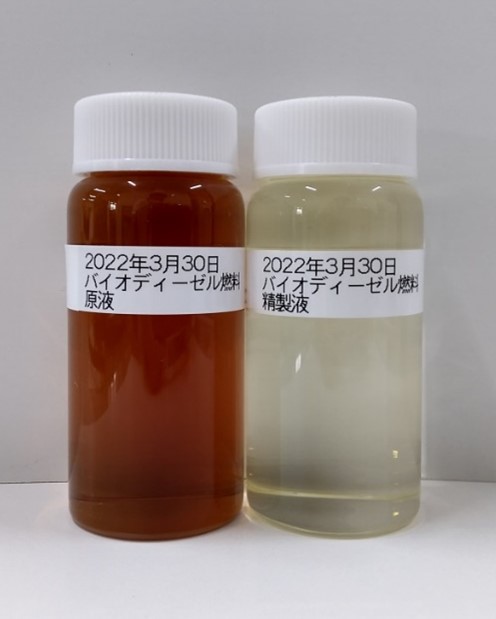

The refined biodiesel fuel is almost transparent because it removes impurities.

Implementation Method

After receiving samples of biodiesel fuel, we undergo laboratory tests and pilot tests, and propose the introduction of actual equipment. We can also provide biodiesel fuel refining equipment and production plant.

About Muromachi Chemical INC.

【Company Profile】

Company name: Muromachi Chemical Inc.

Head Office Location: 1-38-5 Shinkatsudachi-machi, Omuta-shi, Fukuoka Prefecture

President: Junichi Aoki

Established: July 1947

Business: Pharmaceutical manufacturing industry, health food manufacturing industry, ion exchange resin sales and treatment, design and sale of water supply and wastewater treatment equipment, urea solution (AdBlue®), manufacturing, functional adhesive manufacturing

HP:https://www.muro-chem.co.jp

*PURAMEM® is a registered trademark of Evonik Industries AG and is distributed by Polyplastics-Evonik Corporation in Japan.